Waste Tire Recycling Plant

Introduction:Waste tire recycling plant refers to a production line that recycles waste tires into rubber particles. Due to the rapid growth of waste tires, they have gradually become a new source of solid waste pollution, so they need to be recycled.The waste tire recycling production line is a production line that recycles rubber blocks, rubber particles, and rubber powder from waste tires by tearing, crushing, screening, and grinding them.

Classification: The tire recycling production line can be divided into tire cutting production line, tire particle production line, and tire grinding production line according to the discharge demand.

Application field: various rubber products, such as waste tires, rubber soles, waste pipes, rubber conveyor belts, etc. Waste tire is the main raw material.

↓↓↓↓↓

The tires in the above figure can be processed into the following sizes of materials

↓↓↓↓↓

Tire cutting production line:

The tire cutting production line refers to the production line that cuts waste tires into rubber blocks with a diameter of 300-500mm.(tyre block cutting machine)

Put the waste tires (above 1200mm) into a dual axis shredder (with a screening cover) for shredding. After shredding, the qualified materials are screened out through the screening cover, and the unqualified materials are returned to the shredder for shredding, and so on.

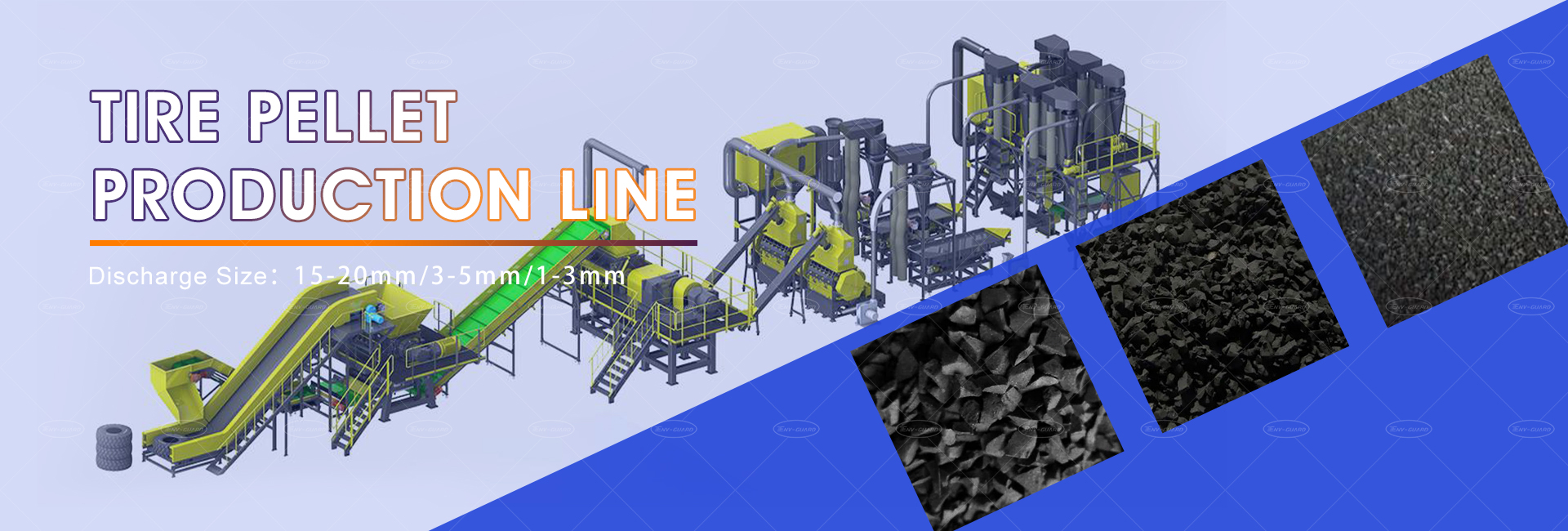

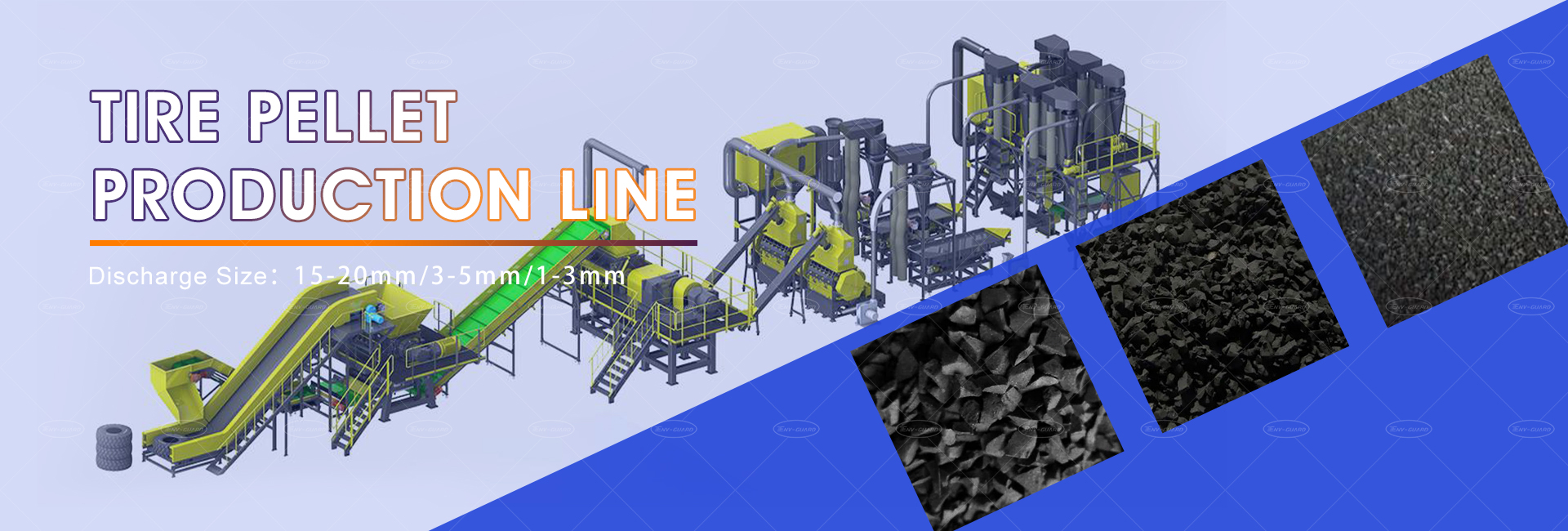

The tire pellet production line:

The tire particle production line can produce three sizes of particles: 15-20mm, 3-5mm, 1-3mm.

The tire particle production line refers to a production line that shreds tires into particles through a shredder. It is divided into 15-20mm coarse particle production lines, 3-5mm medium particle production lines, and 3mm or less fine particle production lines according to the discharge particle size.(tyre granulator machine)

After shredding the waste tires through a shredder, rubber blocks of 50x50mm or larger are obtained. Then, the torn rubber blocks (below 100x100mm) are processed into 10-15mm rubber particles through a steel wire separator. The rubber particles are then separated from the steel wires through a magnetic separator, and the selected rubber particles are transported to a plastic crusher through a screw conveyor for crushing into 3-5mm rubber particles, The rubber particles are separated into fibers and rubber particles through a fiber separator. The separated rubber particles are screened through a linear vibrating screen (3mm mesh, and those exceeding 3mm are returned), and in this cycle, rubber particles below 3mm can be obtained.

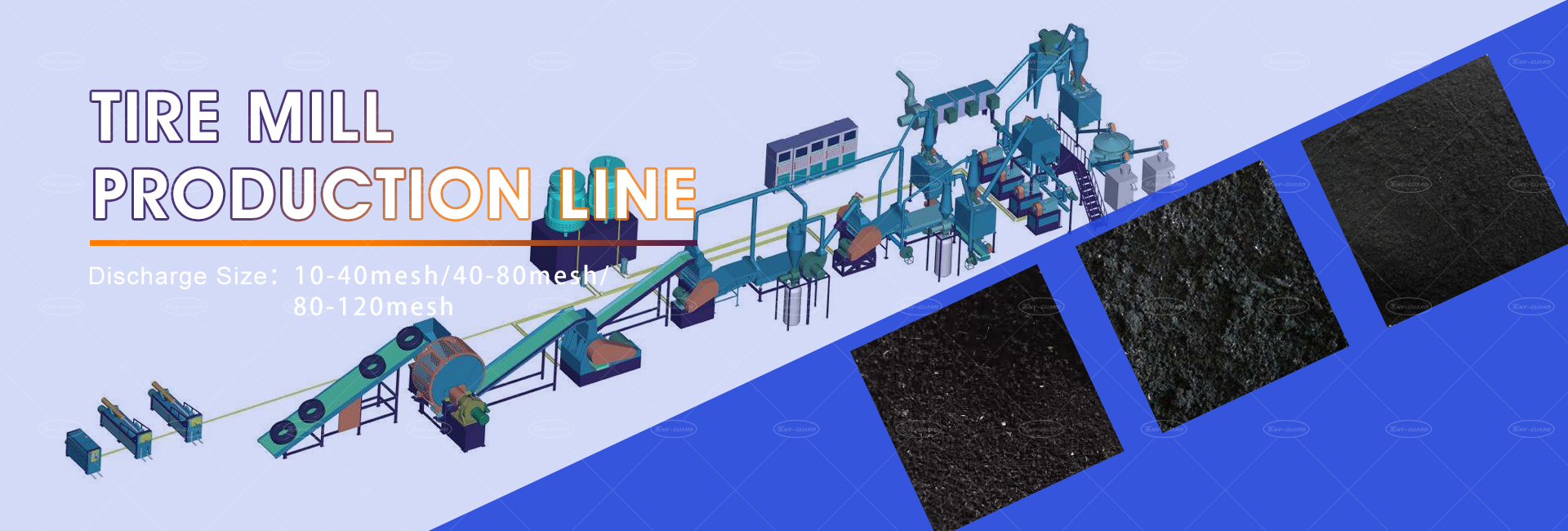

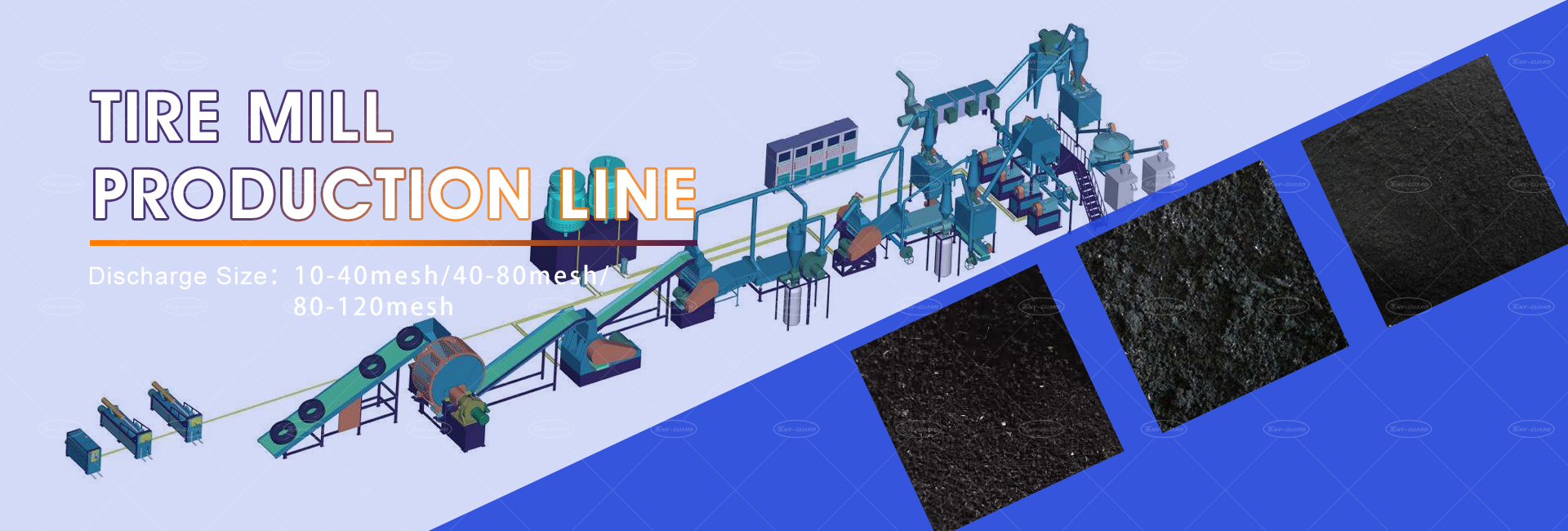

The tire grinding production line:

The tire grinding production line refers to a production line that grinds various waste tires into 5-120 mesh rubber powder.

Waste rubber mixed with steel wires, such as various wheel tires, is extracted by a wire drawing machine and then fed into a dedicated tire shredder by a chain plate machine. This machine is a dual axis shredder combined with a circular drum screen structure, and crushing and screening are carried out simultaneously. The processed materials are then sequentially fed into a steel wire separator. The separated materials are then selected by a magnetic separator, and the steel wires are then transported by a screw conveyor to a crusher for crushing, The crushed material is screened through a linear vibrating screen, and then qualified materials are screened through the linear vibrating screen and fed into the grinding machine to obtain a certain mesh of qualified rubber powder.

Configuration scheme:Henan Shunzhi Machinery can provide customers with waste tire recycling plants with different capacities, from 100 kg/h to 3000 kg/h. The rubber powder size is 10 mesh, 20 mesh, 30 mesh, 40 mesh, 60 mesh, 80 mesh and Max 120 mesh.

For specific configuration plans, please consult Henan Shunzhi Machinery

Advantages:

1. Machine matching can be carried out according to customer needs, with higher degrees of freedom.

2. The entire production line has no waste and the production environment is excellent.

3. High degree of automation and low labor costs.

4. High flexibility, capable of handling various rubber materials.

Consultation

Consultation